Differences Between Biological Safety Cabinets and Laminar Flow Cabinets

Discover how Modular Cleanrooms scale operations efficiently and futureproof facilities, from small specialist spaces to full facility-scale cleanrooms.

How Modular Cleanrooms Help Companies Scale Operations

Discover how Modular Cleanrooms scale operations efficiently and futureproof facilities, from small specialist spaces to full facility-scale cleanrooms.

Scalable Cleanroom Systems | Insights from Lewis Irish

In an evolving scientific and industrial landscape, laboratories face unprecedented challenges. How can lab environments remain flexible, scalable, and sustainable?

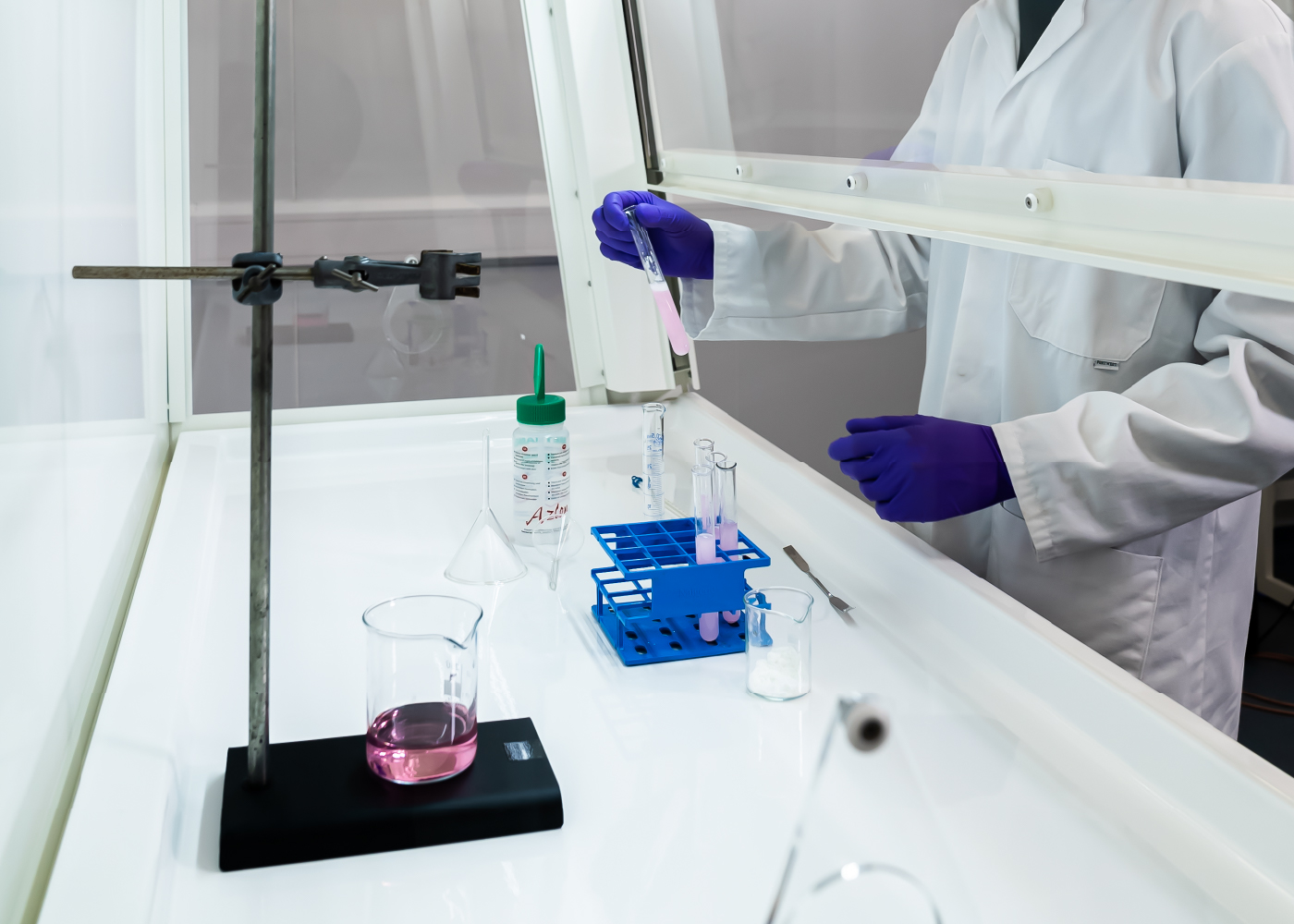

Working in a Biological Safety Cabinet

Good technique when working in a Class 2 Cabinet will minimise turbulence, splatter or unwanted aerosols and maximise protection.

Anti-Static Technologies in Pharma Manufacturing.

Enhance safety in the pharmaceutical industry with by integrating anti-static technology.

Complete Guide to Clean Tents.

The Clean Tent offers a unique and flexible solution for creating controlled environments.

Fume Cupboard Do’s & Don’ts

For a fume cabinet to a provide this critical measure of protection, it’s important for technicians to use it effectively.

What to ask when investing in a Fume Cupboard.

These ventilated enclosures enable laboratory personnel to safely work with materials that produce hazardous fumes.

Applications for a Laminar Flow Cabinet.

Particle-free environments for applications such as tissue culture, electronic parts assembly, and data recovery.

Complete Guide to Clean Air Filters.

[vc_row][vc_column][edgtf_section_title position="" title_tag="h1" text_font_weight="" title="Clean Air Filters Explained: Types, Applications, and Best Practices" title_color="#38B0E3"][vc_separator color="custom" align="align_left" border_width="2" el_width="50" css=".vc_custom_1756817189655{padding-top: 50px !important;padding-bottom: 50px !important;}" accent_color="#E7E8E9"][vc_column_text css=""] Activated Carbon Filters High temperature steam activation leads to a slow and controlled destruction of the

How is a Cleanroom’s Cleanliness Measured?

[vc_row][vc_column][edgtf_section_title position="" title_tag="h1" text_font_weight="" title="The Science of Cleanroom Cleanliness Measurement" title_color="#38B0E3"][vc_column_text css=""] As a self-contained, particulate free environment a cleanroom’s cleanliness is measured by how clean the air is and by the number and size of particles permitted per volume of

HEPA Filtration and Particle Control.

Discover how HEPA filters work and the benefits they offer in life science applications to enhance safety and efficiency.

Activated Carbon Filtration and Fume Containment.

Activated carbon filtration in recirculating fume cupboards provides a safe, efficient, and environmentally friendly solution for managing hazardous fumes.

Factors in choosing the ISO class of a Cleanroom

[vc_row][vc_column][edgtf_section_title position="" title_tag="h1" text_font_weight="" title="Key Considerations for the Appropriate ISO Class for Your Cleanroom" title_color="#38B0E3"][vc_column_text css=""] How Particle Size Impacts Classification If a cleanroom has been designed and built in a clean environment and constructed from non-particulating materials, then air flow is

Complete Guide to Horizontal or Vertical Laminar Flow?

[vc_row][vc_column][edgtf_section_title position="" title_tag="h1" text_font_weight="" title="Selecting the correct Laminar Flow Cabinet." title_color="#38B0E3"][vc_column_text css=""]A Laminar Flow system is vital in the control of particulate contamination. Laminar air flow can be described as an entire body of air flow with steady, uniform velocity.[/vc_column_text][/vc_column][/vc_row][vc_row

Comparing Non-Ducted and Ducted Fume Cupboards.

When it comes to maintaining a safe laboratory environment, selecting the correct fume cupboard is vital.