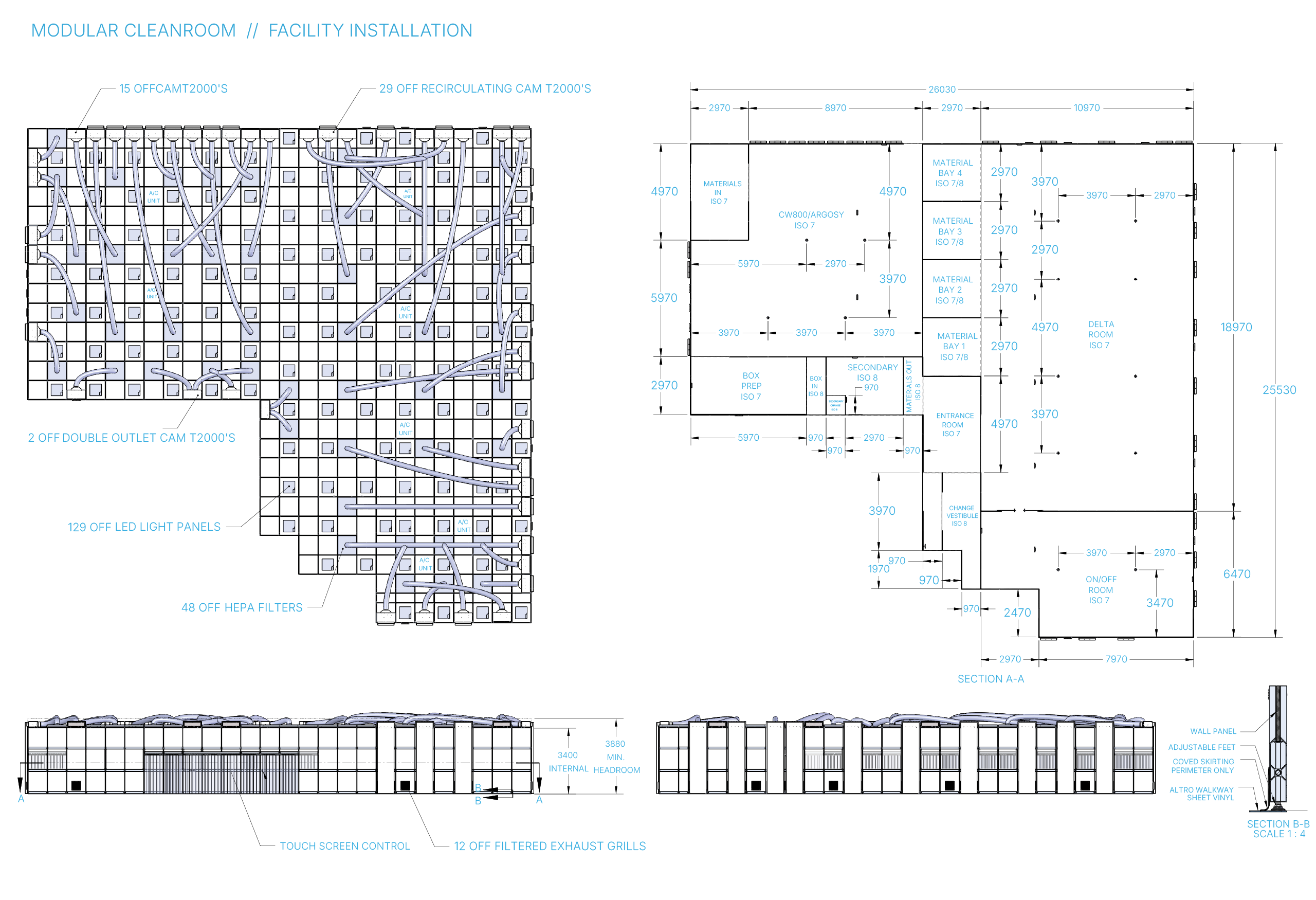

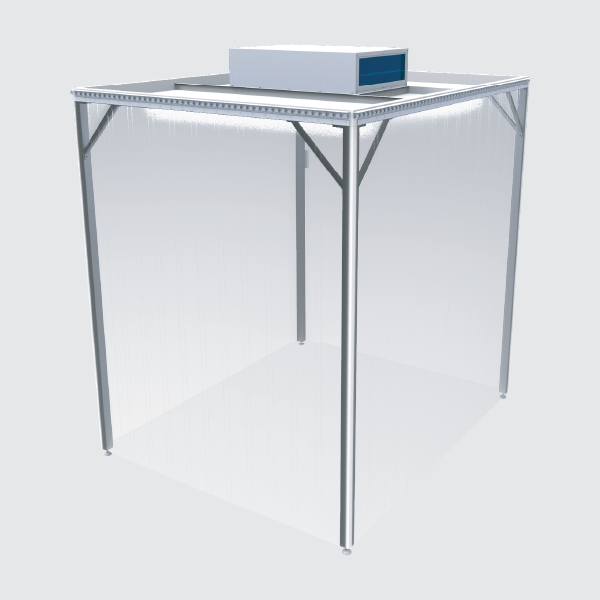

From individual labs to full production facilities, our Modular Cleanrooms are designed to grow with your needs.

Scalable by design, they deliver controlled environments across entire sites.

Electrical Systems

Supply, installation, and certification of all electrical requirements, ensuring that your cleanroom is fully operational.

HVAC Systems

Air quality is one of the most critical factors in performance. Our HVAC systems are designed to meets the highest standards.

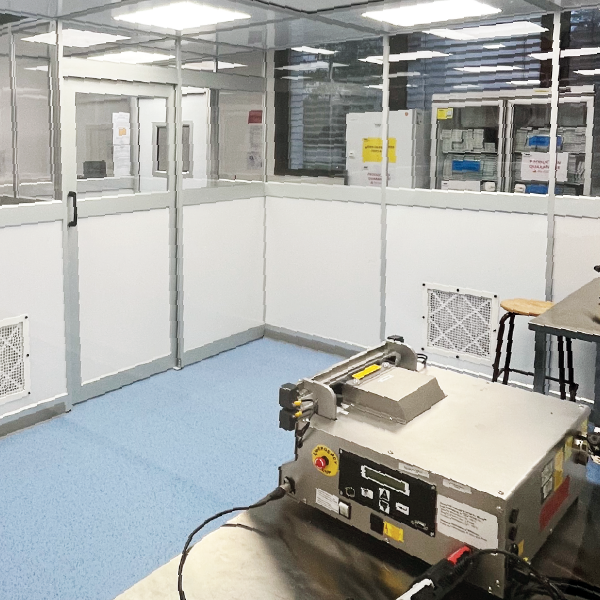

Custom Flooring

Cleanroom flooring needs to be durable, easy to clean, and compliant with strict standards.