How Modular Cleanrooms Help Companies Scale Operations

Technical Insights: Facility-Scale Modular Cleanrooms for ISO-Compliant Environments.

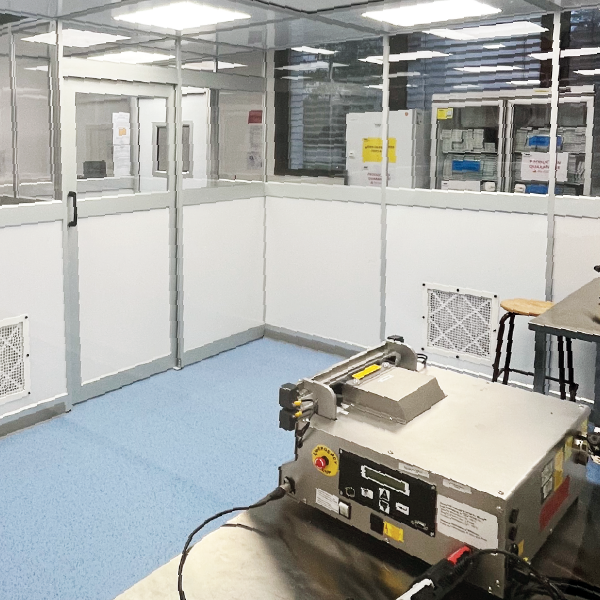

Monmouth Scientific’s Modular Cleanroom combine ISO Class 6–9 performance with the flexibility and speed modern businesses need to grow. Designed for facility-scale operations, these turnkey solutions can be configured for small, specialised cleanrooms through to large production areas, multi-zone workflows, and complex laboratory environments.

Unlike traditional cleanrooms, Modular Cleanrooms are fast to install, easy to expand, and simple to reconfigure, enabling companies to scale efficiently, optimise production, and maintain regulatory compliance.

The system incorporates an aluminium structure and prefabricated polycarbonate panelling to create a fully configurable controlled environment that delivers consistent ISO 14644-1 compliance. This design approach allows businesses to initially scale operations to meet current production requirements while ensuring the cleanroom remains futureproofed for further expansion as operational demands grow.

–

Technical Note: Monmouth Scientific Modular Cleanrooms do not include humidity control, and optional temperature regulation is provided solely for user/operator comfort, not for process-critical applications.

Scaling Benefits of Modular Cleanrooms.

- Rapid Initial Deployment: For companies starting small, Modular Cleanrooms offer a fast, turnkey solution. Prefabricated modules and standardised components allow cleanrooms to be installed quickly, minimising downtime and enabling businesses to begin production under ISO-compliant conditions immediately.

- Futureproofed Expansion: As production grows, Modular Cleanrooms can expand seamlessly. Additional modules, extended layouts, or new multi-zone configurations can be added without disrupting ongoing operations, allowing businesses to scale incrementally or in phases to match operational growth. This ensures a Modular Cleanroom investment remains relevant and adaptable for years to come.

- Facility-Scale Design: Monmouth Scientific can design and install Modular Cleanrooms ranging from small specialist spaces to full facility-scale environments, meeting complex production workflows and large-area requirements. The modular approach ensures that both initial deployment and future expansions maintain ISO Class 6–9 compliance, workflow efficiency, and operational safety.

–

Technical Note: Modular Cleanrooms allow businesses to expand production areas without operational downtime, ensuring workflow continuity and ISO compliance.

Technical Considerations for Scalable Cleanroom Design.

Careful planning is essential to enable scaling while maintaining ISO compliance:

- Airflow and Filtration: HEPA filter sizing and airflow patterns are designed to maintain particulate control within the chosen ISO class while accommodating future expansion.

- Pressure Control: Positive pressure systems prevent contamination ingress, even when modules or zones are added later.

- Workflow Layouts: Modular interfaces, changing areas, and transfer points are planned to support both current production and future growth.

- User Comfort: Optional temperature control maintains operator comfort without affecting process integrity.

This approach ensures the Modular Cleanroom is scalable from day one, reducing the need for costly redesigns or operational interruptions when scaling operations.

Case Study: WOMED.

WOMED, a biotechnology company specialising in women’s reproductive health, expanded its ISO Class 7 cleanroom using a Modular Cleanroom:

- Challenge: Scale production while maintaining ISO compliance without halting ongoing operations

- Solution: Monmouth Scientific added modular units, HEPA filtration, and a changing atrium

- Outcome: Rapid installation, uninterrupted production, and improved workflow efficiency, demonstrating how Modular Cleanrooms support both initial scaling and futureproofed expansion.

Scaling Your Operations with Modular Cleanrooms.

Modular Cleanrooms provide a strategic solution for companies looking to scale operations efficiently and futureproof their facilities. With ISO Class 6–9 performance, rapid installation, flexible layouts, and the ability to design from small specialist spaces to full facility-scale cleanrooms, they ensure businesses can meet current production needs while remaining adaptable for future growth.

Trusted by Leading Facilities.

References.

- Monmouth Scientific. Modular Cleanroom. https://monmouthscientific.co.uk/product/modular-cleanroom/

- ISO. ISO 14644-1: Cleanrooms and associated controlled environments – Classification of air cleanliness. https://www.iso.org/standard/53394.html

- Monmouth Scientific. WOMED Case Study. https://monmouthscientific.co.uk/case-studies/womed/