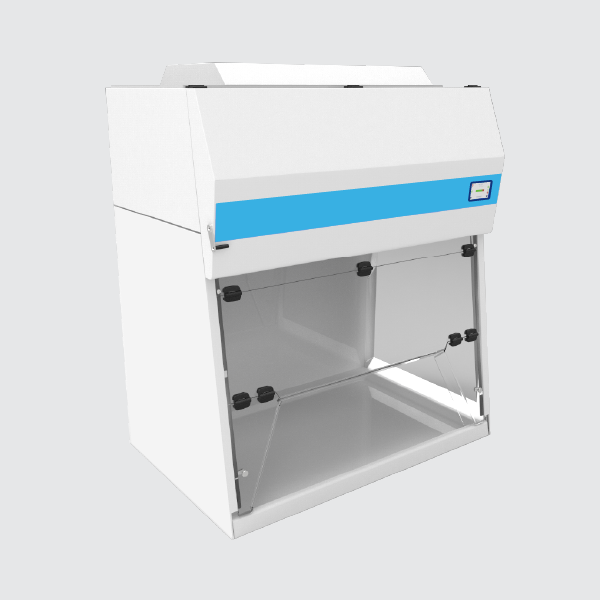

An ATEX Rated Fume Cupboard is a requirement if your unit is to be located in an area with potentially flammable atmospheres. Areas with potentially flammable atmospheres must be void of sparks, including electrical components inside and outside of the unit’s airstream.

Product Description.

The Circulaire® ATEX Rated Fume Cupboard is engineered to provide optimal safety and performance in laboratories, chemical processing facilities, and environments that deals with volatile or explosive materials.

Equipped with high-efficiency filtration systems and robust containment, it is designed to safeguard both personnel and the workspace.

Our ATEX Fume Cupboard’s air filtration and containment performance meets ATEX Essential Health and Safety Requirements and complies with EN13463-1:2009. A specially engineered under-cupboard, containing ATEX Rated fan systems and a Vane Anemometer monitors the airflow to guarantee protection for your laboratory personnel and environment.

The fume cupboard operates by drawing contaminated air through its activated carbon filtration system, where harmful gases, vapours, and particulates are removed. Air is then safely expelled back into the room.

The unit is equipped with ATEX-rated components to prevent ignition sources from interacting with potentially explosive atmospheres, ensuring a safe working environment.

What does ATEX (EX) mean? Our ATEX Rated Fume Hoods are not designed to contain explosions. ATEX is a combination of directives describing equipment and working environments allowed within an explosive atmosphere. Therefore an ATEX unit is designed to eliminate spark potential outside of the unit and reducing the chances of ignition within a flammable atmosphere.

Solution

The Circulaire® ATEX Rated Fume Cupboard is engineered to provide optimal safety and performance in laboratories, chemical processing facilities, and environments that deals with volatile or explosive materials.

Equipped with high-efficiency filtration systems and robust containment, it is designed to safeguard both personnel and the workspace.

Filtration Fume Cupboards can be installed anywhere within your workspace. Our advanced filtration technology, capture and absorbs pollutants produced during chemical handling at source, removing the requirement for ducting to an external environment.

Operation

The fume cupboard operates by drawing contaminated air through its activated carbon filtration system, where harmful gases, vapours, and particulates are removed. Air is then safely expelled back into the room.

The unit is equipped with ATEX-rated components to prevent ignition sources from interacting with potentially explosive atmospheres, ensuring a safe working environment.

What does ATEX (EX) mean? Our ATEX Rated Fume Hoods are not designed to contain explosions. ATEX is a combination of directives describing equipment and working environments allowed within an explosive atmosphere. Therefore an ATEX unit is designed to eliminate spark potential outside of the unit and reducing the chances of ignition within a flammable atmosphere.

Monmouth Scientific’s ATEX Fume Cupboard’s air filtration and containment performance meets ATEX Essential Health and Safety Requirements and complies with EN13463-1:2009. A specially engineered under-cupboard, containing ATEX Rated fan systems and a Vane Anemometer monitors the airflow to guarantee protection for your laboratory personnel and environment.

Technical Specification.

| Model | EX1400 | EX1100 |

|---|---|---|

| External Dimensions: | 1400mm (w) x 900mm (d) x 2470mm (h) | 1100mm (w) x 900mm (d) x 2470mm (h) |

| Internal Dimensions: | 1385mm (w) x 680mm (d) x 1200mm (h) | 1085mm (w) x 680mm (d) x 1200mm (h) |

| Aperture Size: | 1120mm average (w) x 280mm (h) | 820mm average (w) x 280mm (h) |

| Airflow Requirements: | 650m3/h | 475m3/h |

| Airflow Monitoring: | Vane Anemometer | |

| Face Velocity: | 0.55m/sec | |

| Main Filter Type: | 2 x 16kg Carbon or large capacity HEPA | 2 x 14kg Carbon or large capacity HEPA |

| Outlet Filter Type: | 2 x 5Kg Carbon or large capacity HEPA | 2 x 4Kg Carbon or large capacity HEPA |

| Pre-filter: | SafeChange system (95% efficient at 0.5microns) | |

| Internal Lighting: | Atex rated explosion proof lamp | |

| Electrical Requirements: | 230V / 50Hz AC – 1200w | 230V / 50Hz AC – 750w |

| Noise Level: | circa. 59db(A) | circa. 57db(A) |

| Construction: | Fully welded brushed stainless steel | |

Product Catalogue

Features & Benefits.

Recirculating Technology

Eliminates expensive external ducting, simplifies installation, and makes the unit portable for flexible positioning.

Activated Carbon Filteration

Captures a wide range of chemicals and particulates, ensuring a cleaner and safer working environment.

EN 13463 - 1:2009

Fully compliant for ATEX Essential Health and Safety Requirements.

Explosive Environment Rated

All electrical components including sockets, lighting and airflow monitoring system are suitable for ATEX environments.